China 6 Axis 1800mm Arm reach Automatic Steel MIG Welding Robotic Arm

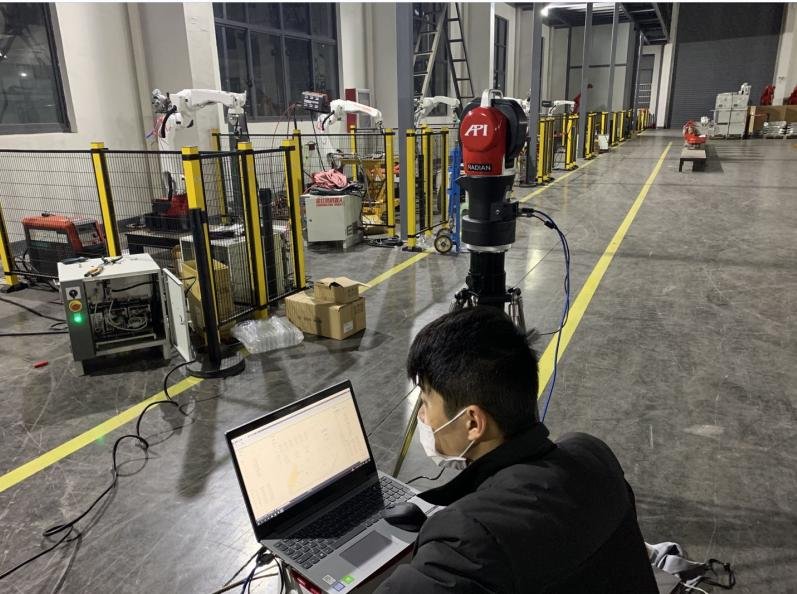

LASER CALIBRATION TEST REPOSITIONING ACCURACY

JHY uses laser calibration method to test the repeated positioning accuracy of the robot. After many tests, the repeated positioning accuracy of our robot is much higher than ±0.08mm.

USE TOP BRANDS FOR CORE ACCESSORIES

Robot core accessories such as servo motor, RV reducer, harmonic reducer, servo drive and so on all use China's top brands, which have been tested by our long-term use to ensure that they are suitable for our robot.

SIMPLE MAINTENANCE

Maintenance is simple, According to the maintenance guide provided by us customers themselves can easily operate.

AFTER SALE GUARANTEE

Every customer has its own after-sales service group. If you need any after-sales help, Pls ask at any time. Our professional engineers will solve it in the shortest time. The point is it's all free.

|

Welding parameters reference for mild steel and low alloy steel |

|||||||||

|

type |

plate |

Wire diameter |

root gap |

welding current |

welding voltage |

welding speed |

Contact tip-workpiece distance |

Gas flow |

Welding angle |

|

T-shaped butt welding |

1.0 |

0.8 |

2.5~3 |

70~80 |

17~18 |

8~10 |

10 |

10~15 |

45° |

|

1.2 |

1.0 |

3~3.5 |

85~90 |

18~19 |

8~10 |

10 |

10~15 |

45° |

|

|

1.6 |

1.0,1.2 |

3~3.5 |

100~110 |

18~19.5 |

8~10 |

10 |

10~15 |

45° |

|

|

2.0 |

1.0,1.2 |

3~3.5 |

115~125 |

19.5~20 |

8~10 |

10 |

10~15 |

45° |

|

|

2.3 |

1.0,1.2 |

3~3.5 |

130~140 |

19.5~21 |

8~10 |

10 |

10~15 |

45° |

|

|

3.2 |

1.0,1.2 |

3.5~4 |

150~170 |

21~22 |

7.5~8 |

15 |

15~20 |

45° |

|

|

4.5 |

1.0,1.2 |

4.5~5 |

180~220 |

21~23 |

6.5~7.5 |

15 |

15~20 |

45° |

|

|

1.2 |

5~5.5 |

200~250 |

24~26 |

6.5~8 |

10~15 |

10~20 |

45° |

||

|

6 |

1.2 |

5~5.5 |

230~260 |

25~27 |

6.5~7.5 |

20 |

15~20 |

45° |

|

|

6 |

220~250 |

25~27 |

5.5~7.5 |

13~18 |

10~20 |

45° |

|||

|

4~4.5 |

270~300 |

28~31 |

10~11.5 |

13~18 |

10~20 |

45° |

|||

|

8,9 |

1.2,1.6 |

6~7 |

270~380 |

29~35 |

6.5~7.5 |

25 |

20~25 |

50° |

|

|

8 |

1.2 |

5~6 |

270~300 |

28~31 |

9~10 |

13~18 |

10~20 |

45° |

|

|

1.2 |

7~8 |

260~300 |

26~32 |

4~5.5 |

15~20 |

10~20 |

50° |

||

|

1.6 |

6.5~7 |

300~330 |

30~34 |

5~5.5 |

15~20 |

10~20 |

50° |

||

|

12 |

1.2,1.6 |

7~8 |

270~380 |

27~35 |

4.5~6.5 |

20~25 |

20~25 |

50° |

|

|

1.2 |

7~8 |

260~300 |

26~32 |

4~5.5 |

15~20 |

10~20 |

50° |

||

|

1.6 |

6.5~7 |

300~330 |

30~34 |

5~6 |

15~20 |

10~20 |

50° |

||

Note:

1. MIG welding uses inert gas, mainly used for welding of aluminum and its alloys, copper and its alloys, titanium and its alloys, as well as stainless steel and heat-resistant steel. MAG welding and CO2 gas shielded welding are mainly used for welding carbon steel and low alloy high strength steel.

2. The above content is for reference only, and it is best to obtain the optimal welding process parameters through experimental verification. The above wire diameters are based on actual models.