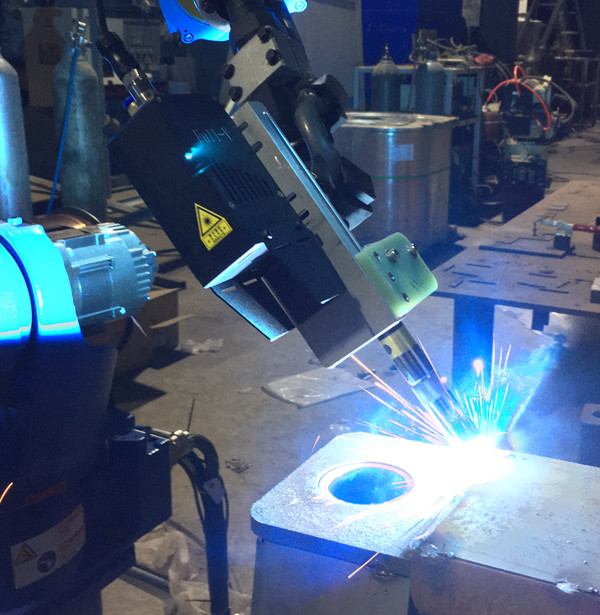

In the actual welding process, in order to avoid danger when the robot is working, the operator is not allowed or should not enter the working area of the robot, so that the operator cannot monitor the welding process in real time and make the necessary adjustment, so when the conditions change, such as happening the dimensional error and position deviation of the workpiece during the welding and assembly process, and the heating deformation of the workpiece, the joint position deviates from the teaching path, may causing the welding quality to decline or even fail.

When do we need to equip the welding robot with laser vision?

In arc welding, if the welding accuracy cannot be guaranteed to reach ±0.3mm, it is necessary to consider the use of laser positioning or laser tracking. To select a laser vision welding seam tracking system, you first need to verify whether it interferes with the tooling fixture, and secondly, consider whether it will affect the time beat. If both not, then the laser can be fully integrated into the robot workstation.

The basic inspection principle of laser vision welding seam tracking

The basic principle of laser seam tracking is based on the laser triangle measurement method. The laser emits line laser light to the surface of the workpiece, and after diffuse reflection, the laser contour is imaged on the CCD or CMOS sensor. The controller then processes and analyzes the collected images to obtain the position of the weld, which is used to correct the welding trajectory or guide the welding.

What is laser tracking?

Laser tracking uses a laser vision sensor to detect the weld in advance before the welding torch , , and calculates the position coordinates of the sensor measurement point through the pre-calibrated positional relationship between the laser vision sensor and the torch. During the welding process, the robot’s teaching position and the sensor’s position are calculated. The detection positions are compared, and calculate the position deviation of the corresponding point. When the welding gun lagging behind the laser line reaches the corresponding detection position, the deviation is compensated to the current welding trajectory to achieve the purpose of correcting the welding trajectory.

What is laser positioning?

Laser positioning is the process of using a laser sensor to make a single measurement of the position to be measured and calculating the position of the target point. Generally, when with a short welding seam or the use of laser tracking interferes the tooling fixture, the welding seam is corrected in the form of laser positioning. Compared with laser tracking, the function of laser positioning is relatively simple, implementation and operation It is also more convenient. However, since it is detected first and then welded, the positioning is not suitable for welding workpieces with severe thermal deformation and irregular welds that are not straight lines or arcs.

Post time: Oct-22-2022