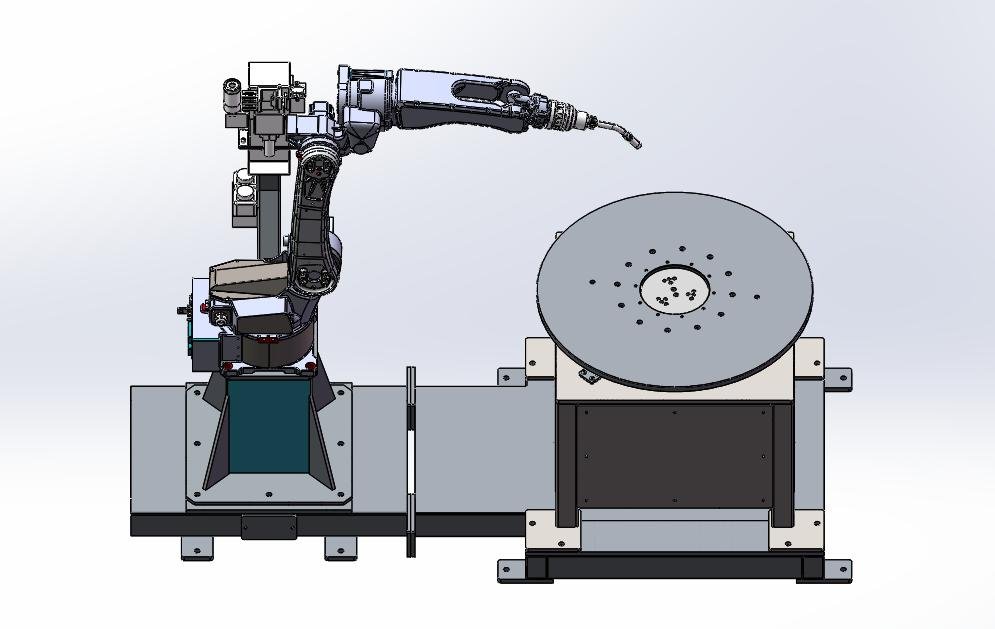

6 Axis stainless steel aluminium welding robotics workstation

Feature

1. The robot’s built-in cable design allows the robot to move without interference and the workstation layout is neat and tidy

2. The robot control cabinet can control up to 11 axes, avoiding complex PLC debugging and space occupation

3. The JHY robot and the positioner can be synchronised, and the robot can weld simultaneously when the positioner is rotating, making this workstation particularly suitable for circular welding.

4. A wide range of ancillary equipment is available, such as laser sensors, safety light curtains and safety fences.

5. The control system contains several welding process packages, which allow different welding modes to be used for different workpieces.

Positioner technical parameter

|

Model |

JHY4030D-080 |

|

Rated Input Voltage |

Single-phase 220V, 50/60HZ |

|

Motor Insulation Calss |

F |

|

Work Table |

Diameter 800mm(can be customized) |

|

Weight |

About 400kg |

|

Max. Payload |

Axial Payload ≤300kg / ≤500kg / ≤1000kg(>1000kg can be customized) |

|

Repeatability |

±0.1mm |

|

Stop Position |

Any Position |

Robot workstation Components

1.Welding robot:

Type: MIG welding robot-BR-1510A,BR-1810A,BR-2010A

TIG welding robot:BR-1510B,BR-1920B

Laser welding robot:BR-1410G,BR-1610G

2.Positioner

Model: JHY4030D-080

Type: 1-axis horizontal rotating positioner

3.Welding power source

Type: 350A/500A welding power source

4.Welding gun

Type: air-cooled gun,water-cooled gun,push-pull gun

5.Torch clean station:

Model:SC220A

Type: Automatic pneumatic welding torch cleaner

Other robot workstaion peripheral

1.Robot moving rail

Model: JHY6050A-030

2.Laser sensor (optional)

Function: weld tracking, positioning.

3.Safety light curtain (optional)

Protective distance: 0.1-2m,0.1-5m; protective height: 140-3180mm

4.Security fence (optional)

5.PLC cabinet(optional)