2 axis heavy payload servo positioner

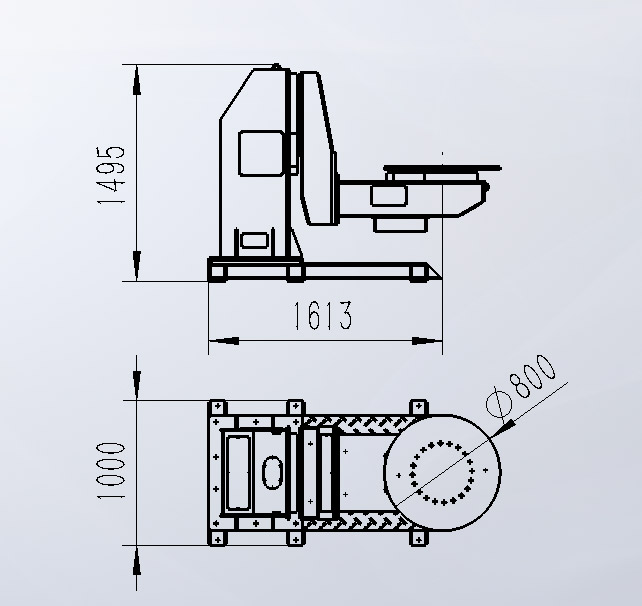

Positioner Dimensions

Description

- How this 2 axis L positioner moves?

1 axis can rotate 360°horizontally,the other 1 axis can flip 360° left and right

Welding positioner normally composed by worktable slewing mechanism and turnover mechanism, which let the work piece that fixed on the worktable in the desired welding or fitting angle by worktable’s lifting, turnover and slewing.

- How the positioner works?

The welding positioner series are side tipping type, head and tail rotation type, head and tail lifting rotation type, head and tail inclined type and double rotation type,etc.

It’s can match with welding manipulator to form into automatic special welding machine, and it’s also match with robot peripheral equipment and robot to realize welding automation. And we also can make customized welding positioner according to clients’ different work piece and technological requirements.

Positioner Diameter

|

Model |

JHY4030L-080 |

|

Rated Input Voltage |

Single-phase 220V, 50/60HZ |

|

Motor Insulation Class |

F |

|

Turntable |

Diameter 800mm(can be customized) |

|

Weight |

About 400kg |

|

Max. Payload |

Axial Payload ≤300kg / ≤500kg/ ≤1000kg (>1000kg can be customized) |

|

Repeatability |

±0.1mm |

|

Stop Position |

Any Position |

Application

Auto parts,bicycle parts, car parts, steel furniture, new energy,steel structure, construction machinery,fitness equipment,etc.

Main products of our welding positioner

1 axis head-tail rotate type welding positioner

1 axis head-stock vertical rotate welding positioner

1 axis horizontal rotating welding positioner

2 axis P type welding positioner

2 axis U type welding positioner

2 axis L type welding positioner

3 axis horizontal welding positioner

3 axis up-down flip welding positioner

Package :Wooden cases

Delivery time: 40 days after prepayment received

FAQ

1.Q: can your positioner work with my Fanuc robot?

A: Yes

2.Can your positioner move in sync with my ABB robot?

A:Yes, just install the same brand motor as your robot on the positoner.

3.Q: How is the positioner controlled?

A: When you use JHY robot, then it can controlled by our robot control system; when you use other brand robot, we can equip the positioner with a PLC cabinet to work with your robot.