pipe turning welding positioner with motor servo

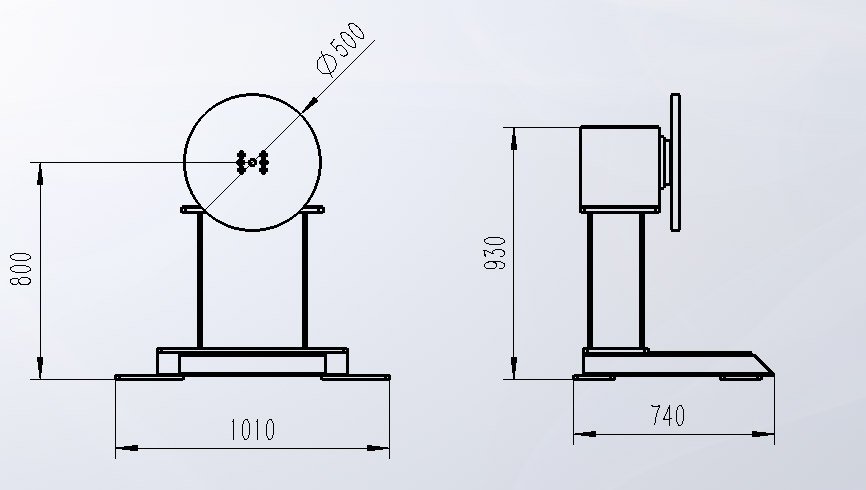

Positioner Dimensions

Description

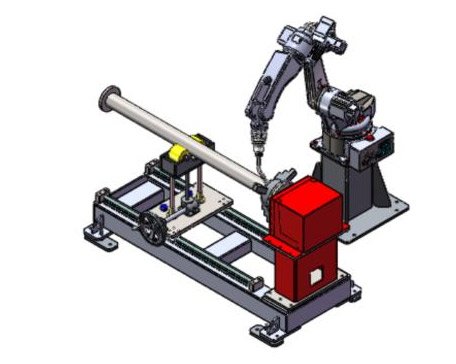

- This pipe welding positioner is used for diverse applications ranging from pipe spooling to positioning of very long parts such as chassis components or street light pole.

- Welding positioners greatly enhance productivity when welding pipe, shafts, wheels, elbows and other fittings.

- Welding turntable size and axis payload can be customized, chucks and support wheel are available.

- Can be adapted to other brands of robots like – Fanuc,ABB,KUKA,Yaskawa.(motor drawing need to be offered by customers,then we leave the installation hole based on the motor drawing)

- PLC cabinet are in optional.

Positioner Diameter

|

Model |

JHY4010T-050 |

|

Rated Input Voltage |

Single-phase 220V, 50/60HZ |

|

Motor Insulation Class |

F |

|

Work Table |

Diameter 500mm(can be customized) |

|

Weight |

About 400kg |

|

Max. Payload |

Axial Payload ≤100kg / ≤300kg/ ≤500kg (can be customized) |

|

Repeatability |

±0.1mm |

|

Stop Position |

Any Position |

Application

Auto parts,bicycle parts, car parts, steel furniture, new energy,steel structure, construction machinery,fitness equipment,etc.

Package :Wooden cases

Delivery time: 40 days after prepayment received

FAQ

1.Q: How to choose your welding psitioners?

A:Pls tell us the weight,dimensions of your workpiece and show us the photos of its welding position,then we will recommend you the suitable welding positioner.

2.Q: Can i use your positioner for my fanuc/abb/kuka/yaskawa robot?

A:Yes. But the motor need to be offered and installed by yourself.

3.Q: Do you accept customized order?

A: Yes, we could design the positioner with different payload and worktable size.